Improve cut accuracy with a guide rail square

The plunge saw, also referred to as a guide rail or track saw, has become our most popular selling powered portable saw, outstripping conventional circular saw sales threefold! Whether it be a mains powered – using an electric cable, or cordless – using a battery powered motor, plunge saws have become the ‘go to’ option for many trade professionals. The difference between a traditional circular saw and plunge saw is explained in more detail, in a previous blog ‘plunge saw vs traditional circular saw’.

The main reason for choosing a saw which runs on a rail is for the ability to make repeatable, straight cuts. In essence you are combining machine like precision with freehand speed… that’s great eh? Well, yes and no. The action of making the cut is very quick and easy, but this is only possible because of previous measuring and marking. Most people will have heard the old saying ‘measure twice, cut once’… and this is indeed sound advice. However, constant rechecking can take up valuable time.

The guide rail used on these types of saws is quite simply a straight edge for the saw to run ‘in’ rather than ‘against’, as would be the case when using a traditional side fence. The user is required to measure and mark on one side of the material to be cut and then measure and mark again at the other end. The accuracy of these measured marks is critical, especially when cutting sheet material, as the margin of error is greatly exaggerated on longer cuts. The guide rail is then used as a tool to join up this ‘dot to dot’ system in order to make the cut. As a portable saw system, the plunge saw and guide rail is unquestionably far superior than the traditional circular saw and fence method, but still… what a faff!

Enter into the process a Taiga Tools precision engineered rail square. In summary, this attachment turns your guide rail into a huge try square, allowing the user to make 90 degree cuts with an incredible accuracy of between 0.005 – 0.007 degrees. If you were to look up the description of a ‘try square’ it reads: ‘an implement used to check and mark right angles in construction work’… so what better reference to work from! Now the cutting process is easier and more accurate than ever:

- Measure and mark just ONE side

- Align the guide rail with Taiga Square attached to your cutting mark

- Make a fast and accurate 90 degree cut

- No need to measure and mark both ends, no clamping required and no wasted material from misaligned cuts!

Does this all sound too easy? Believe me, a huge amount of thought and precision engineering has gone into making the Taiga Rail Square. Wim Pauwels is the Finnish founder and brainchild of Taiga Tools. Obsessed with detail and accuracy, Wim has reworked and improved upon a number of existing tool accessories used in conjunction with established brands, believing that users of the tools deserve more robust and accurate attachments for the equipment they have invested in. This is no different in the case of the Taiga Precision Rail Square.

The Taiga Rail Square is machined on the latest CNC equipment using 6082 aluminium, which is the highest strength aluminium in the 6000 series. 6082 aluminium is typically used in the construction of trusses, bridges and cranes – but due to its very low weight and incredible strength, this grade aluminium is also the ultimate material for manufacturing precision components.

At the end of the machining process, the aluminium is then anodised to give further protection from wear and corrosion. Every square is then hand assembled and checked with a probing system, so the stated tolerances can be guaranteed. Some may argue that the Taiga Rail Square is over-engineered, but what the heck… better to be over-engineered, last a lifetime and be unbelievably accurate rather than under-engineered, flimsy and out-of-square right? Let’s not forget, this attachment is designed to work alongside absolute top quality and premium portable power tools!

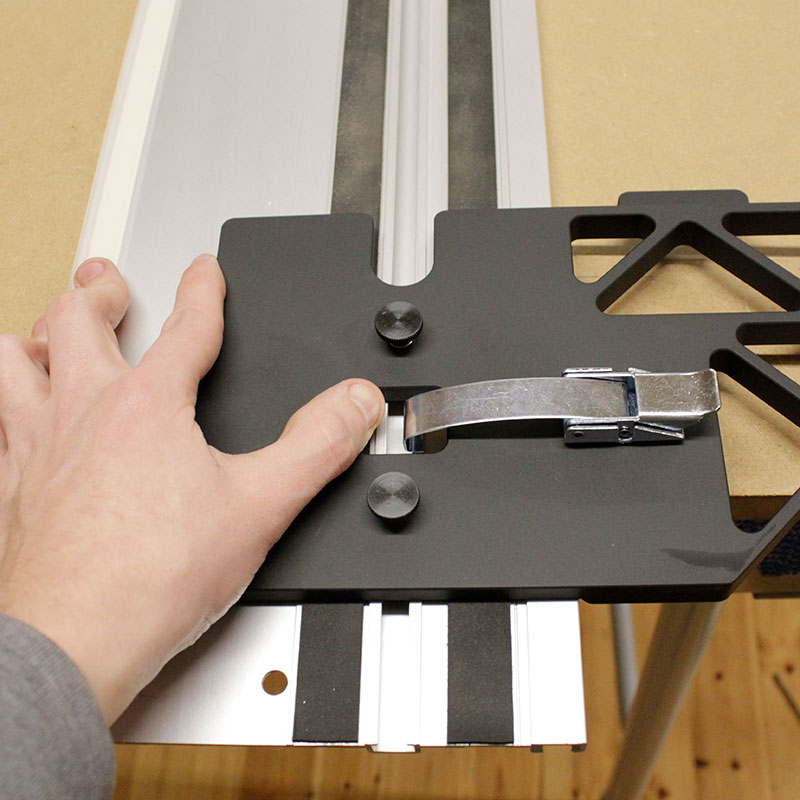

The Taiga Rail Square isn’t just robust… it’s also very clever. There are two tabs which rest on the top of the workpiece, ensuring the guide rail remains flat on the material that is being cut. These tabs also ensure the rail does not wobble or move during the cutting action, which means that the need for clamping is negated. Sometimes, less is more… and that is why the Taiga Rail Square has absolutely no adjustment. Adjustable squares can often cause inaccuracies during set-up, especially when they become worn or are simply not tightened-up correctly. Once the Taiga Rail Square is connected to the rail, that’s it… no adjustment, no movement – just 90 degree cuts each and every time. To the point of being obsessive, Wim has also included a lock-off clip which acts to hold the square true on the guide rail once the two knurled screws have been tightened.

The Taiga Rail Square isn’t just robust… it’s also very clever. There are two tabs which rest on the top of the workpiece, ensuring the guide rail remains flat on the material that is being cut. These tabs also ensure the rail does not wobble or move during the cutting action, which means that the need for clamping is negated. Sometimes, less is more… and that is why the Taiga Rail Square has absolutely no adjustment. Adjustable squares can often cause inaccuracies during set-up, especially when they become worn or are simply not tightened-up correctly. Once the Taiga Rail Square is connected to the rail, that’s it… no adjustment, no movement – just 90 degree cuts each and every time. To the point of being obsessive, Wim has also included a lock-off clip which acts to hold the square true on the guide rail once the two knurled screws have been tightened.

UPDATE: In order to work in conjunction with the most popular guide rail profiles, the original rail square was available in two versions – one to suit Festool, Makita and Triton rails and the other to suit Mafell and Bosch rails. After research, Wim discovered that users preferred to position the square against the rail, by pulling in place with their thumb – using the round recessed hole for leverage. Many users had even removed the clip completely. The feedback resulted in the very last batch of the first generation rail squares being modified slightly, by removing the lock-off clip at production stage.

Towards the end of 2020, Wim was offered an opportunity to work for another tool company based in Finland. He reluctantly decided to call time on his Taiga Tools business, in order to focus on his new role, and announced his intentions via social media. This decision was met with great disappointment all around the globe, from numerous craftsmen who regarded his unique rail square to be the most refined and accurate product available. After a few weeks of deliberation, Wim decided to continue with production – managing to find an alternative local manufacturer with the same levels of precision and refinement.

With production secured, Wim also took the opportunity to redesign the rail square – developing the second generation ‘hybrid’ model, which was expected to be available from April 2021. The latest Taiga Hybrid Rail Square is compatible with most guide rail profiles available on the market – fitting perfectly to all lengths of Festool, Makita, Triton, Evolution, Mafell, Bosch, and even the DeWalt profile guide rails.

Click below for more details on the Taiga Rail Squares and Taiga T-Squares.

Digital Sales Manager, Protrade

Alan has almost 13 years of experience as a customer service advisor at Protrade. Alongside Alan’s customer service role, he is a staff trainer and content creator, who you will typically see across Protrade’s social media channels.