-

Save 40% on Maxitek

Maxitek 115mm Diamond Blade for Mortar Raking

£20.85 exc. VAT£25.02 inc. VAT -

Save 40% on Maxitek

Maxitek 115mm Diamond Blade for Ceramics & Tiles

£12.41 exc. VAT£14.89 inc. VAT -

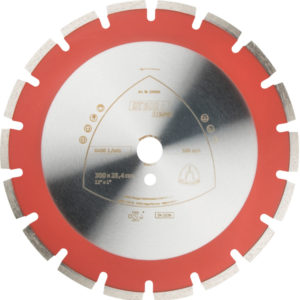

Klingspor DT612AB Supra Diamond Blades for Asphalt/Concrete

£113.55 – £334.12 exc. VAT£136.26 – £400.94 inc. VAT -

Klingspor DT602A Supra Diamond Blades for Asphalt

£91.31 – £259.09 exc. VAT£109.57 – £310.91 inc. VAT -

Klingspor DT602B Supra Diamond Blades for Hard Materials

£106.92 – £214.88 exc. VAT£128.30 – £257.86 inc. VAT -

Klingspor DT600U Supra Diamond Blades for General Use

£107.95 – £214.88 exc. VAT£129.54 – £257.86 inc. VAT -

Save 40% on Maxitek

Maxitek Professional Multi Material Diamond Blades

£6.77 – £25.00 exc. VAT£8.12 – £30.00 inc. VAT -

Metabo 125mm Triple Row Wall Chaser Diamond Blade for MFE40

£99.00 exc. VAT£118.80 inc. VAT -

Husqvarna EL35 Multi Diamond Blade Set for K760 Cut-n-Break

£219.00 exc. VAT£262.80 inc. VAT -

Extra Savings on Milwaukee

Milwaukee 76mm Diamond Blade for M12FCOT Cut-Off Tool

£15.26 exc. VAT£18.31 inc. VAT -

Extra Savings on Milwaukee

Milwaukee 76mm Carbide Blade for M12FCOT Cut-Off Tool

£12.92 exc. VAT£15.50 inc. VAT

Diamond Blades

As diamonds are the hardest substance known to man they can provide an exceptionally hard wearing grit for blades used in the construction industry. Diamond blades have mostly taken over from bonded abrasives in masonry cutting applications because of their cutting speed, continuous depth of cut and long life. In the manufacture of diamond blades a diamond grit is held within a metal carrier, as the metal carrier wears it exposes the diamond grit which does the cutting by removing small chips of the base material. Protrade stock a wide range of diamond blades capable of cutting most materials. Protrade major in Maxitek and Klingspor brands and stock sizes ranging from 115mm through to 500mm. Why not take advantage of our click and collect service? Simply place your order online and collect a diamond blade from any of our Protrade depots located in Chesterfield, Mansfield, Burton Upon Trent, Derby and Nottingham.

The concentration of diamond, size of grit and hardness of the metal carrier all play a part in what the blade will cut, how long it will last in that particular material and what finish it will achieve. Typically, a soft metal carrier is used for very hard base materials as the diamond grit is exposed more easily, for soft and abrasive materials the metal carrier is made harder to prevent the diamond being exposed too easily and the grit being lost prematurely. Lower diamond grit concentration means a shorter life for the blade but lowers manufacturing costs, larger diamond grits result in faster cutting but a coarser finish.

For fine cutting applications such as tile cutting, a continuous rim is required. These blades use a finer grit particle and have a cutting edge that is not segmented, allowing the cutting edge to remain in contact with the surface, thus preventing any chatter and therefore achieving a chip free finish; heat build up is prevalent with these blades so water cooling is essential to keep the blade cool and flush out any waste material.

Diamond blades can always benefit from water cooling where possible; this keeps the metal carrier from overheating promoting longer blade life and also acts as dust suppression which is very important when cutting base materials containing silica. If you are investing in diamond blades you are actually purchasing cuts. It may sound peculiar but the speed of cut and how many you achieve before the blade expires will give you the true cost of the blade; with the introduction of very low cost diamond products this fact is often overlooked but it should remain the most important consideration before investing in a diamond blade.

Showing 11 of 11 products

Loading filters please wait.